RECOGNISING that throatbush wear rate has a major impact in the overall efficiency of slurry pumps, Weir Minerals has developed superior rotating and axial adjustment technology.

In many applications, the pump’s throatbush is the component that has the shortest life compared to the impeller and liners, with considerable variability.

Adjusting the gap between the throatbush and the impeller front shroud reduces hydraulic recirculation in the pump. This prevents localised wear on the throatbush, improves hydraulic efficiency and lowers the total ownership cost for the operator. To avoid impacting the plant’s production, these adjustments are often performed while the pump is operating. However, this can have safety implications for individuals working at the front of the pump unit.

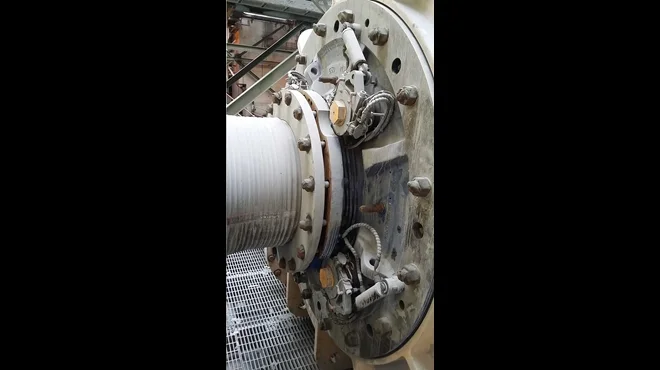

“Manually adjusting an alloy throatbush on a large pump requires several people and is labour intensive. It requires mechanical tools to adjust the four pusher bolts, one at a time, in order to reduce the gap between the throatbush and impeller. We wanted to find a safer and quicker way to extend the wear life of the pump with regular adjustments, which led us to development of this technology,” states Marcus Lane, Global Product Manager for Centrifugal Pumps for Weir Minerals.

“Our automated throatbush adjustment solutions are available for pumps fitted with either rubber or alloy throatbushes on Warman slurry pumps used in the most arduous applications. By mechanising the adjustment procedure, personnel are removed from the line of fire, and the accuracy of axial movement is increased,” states Ron Bourgeois, Director of Slurry Pumping Technology Group for Weir Minerals.

Weir Minerals’ automated adjustment systems speed up the process, allowing for more frequent adjustments with minimal effort. When maintaining an alloy throatbush, all four bolts are adjusted at the same time to ensure even adjustment and accurate positioning, improving the wear life of the throatbush.

Rubber throatbush adjustment is considerably different because it poses the risk of hysteresis and premature failure of the throatbush. The goal is not to adjust to a minimum clearance but to maintain a standard gap to ensure that there is no contact between the impeller and throatbush, whilst periodically rotating the throatbush face to avoid acceleration of localised wear.

“We developed an automated rotating solution which maintains an optimum gap between the throatbush and impeller front shroud for the particles to flow through without catching and tearing the rubber. The localised surface wear is usually near the discharge position, but by slowly rotating the throatbush, we even out the material loss over the entire face. Field results have been very positive, showing an average of 40% increase in wear life,” states Claudio Needham, Application Engineer for Weir Minerals.

For the smaller Warman® slurry pumps used in medium to heavy duty applications, Weir Minerals offers a single point adjustment mechanism, providing both axial and rotational repositioning. This allows one individual to safely stand to the side of the pump while making the adjustment.

Mining operators who have trialled Weir’s adjustment technology have reported improved wear life and safer, simpler maintenance through the process of regular adjustment.