GERMAN polymer manufacturer, igus, is slowly changing the way we do things by replacing metals and other everyday materials with stronger, longer lasting polymers.

In South Africa igus is gaining a reputation for its innovative plastics that can outlast even the strongest traditional materials hundreds of times over and are best known for their exceptional performance, durability and low friction properties.

Among these materials, iglidur stands out as a versatile choice for various applications across many industries. Here are some examples of its most successful uses.

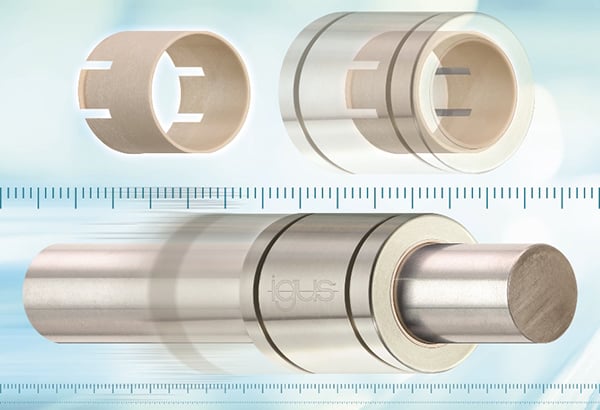

- Bearing Applications

These self-lubricating materials offer low friction, long service life and resistance to wear and tear, making them ideal for applications in automotive, aerospace, and industrial machinery.

2. Food Processing

iglidur materials are a preferred choice due to their FDA compliance, low moisture absorption and corrosion resistance. No lubricants are required for these materials used for various applications, including conveyor systems, bottling equipment and packaging machinery.

3. Material Handling

Conveyor systems, sorting machines and automated warehouses depend on iglidur materials for their low wear and quiet operation.

4. Packaging Machinery

The packaging industry applications, include pick-and-place systems, labelling machines and filling equipment. The self-lubricating properties of iglidur materials reduce downtime and maintenance.

5. Agriculture

iglidur materials materials’ resistance to dirt and dust, combined with their durability, ensures reliable performance in harsh outdoor conditions.

6. 3D Printing

Iglidur materials are employed as 3D printer bushings, providing smooth and precise motion. Their self-lubricating properties eliminate the need for additional lubrication, simplifying the printing process.

7. Offshore and Marine

iglidur materials are employed in winches, cranes, and other machinery used in harsh saltwater environments. Their resistance to corrosion and long service life makes them a reliable choice for these demanding applications.

From the automotive sector to medical equipment, packaging machinery to agriculture, these materials have proven their worth in diverse applications. As industries continue to evolve and demand more from their equipment, igus iglidur materials remain a trusted choice for improving performance and reliability.