DUE to the increasing size and complexity of its recent construction projects, South African company T3 Projects decided to purchase three new mobile cranes from Liebherr.

The LRT 1100-2.1 and LRT 1130-2.1 rough terrain cranes are ideal for hoisting work in inaccessible, remote areas, while the LTM 1300-6.3 mobile crane supplements the performance of the T3 Projects fleet with its maximum lifting capacity of 300 tons.

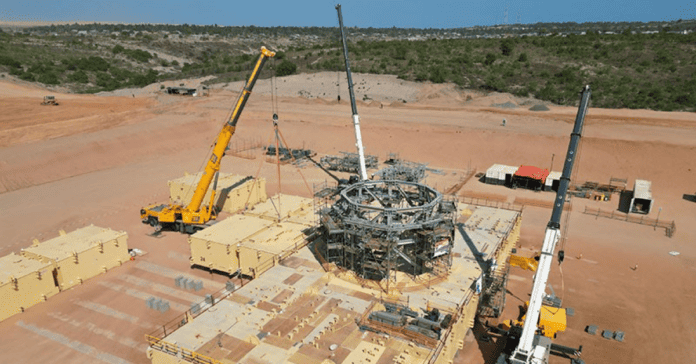

At the Moma Mine in Mozambique, the three new cranes are being used in the construction of a floating platform. Heavy mineral deposits are mined at Moma using three artificial ponds.

“The new cranes represent a significant expansion of our current fleet and deliver unprecedented opportunities for high capacity hoisting work that our current equipment cannot handle,“ says Richard van den Barg, MD at T3 Projects, adding: “We will use the cranes for loading heavy materials, erecting structures and carrying out high precision hoisting work.

“As we often work in harsh conditions, we rely on high-quality, robust and powerful equipment. We therefore opted for Liebherr cranes, as they are widely recognised for their reliability and durability. Liebherr’s customer service also has an excellent reputation. The rapid support in the event of problems, comprehensive maintenance packages and the high availability of spare parts ensure that downtimes are minimised and our projects run smoothly,” says Donovan Carroll, operations director at T3 Projects, underlining his confidence in the German crane manufacturer.

Based on his many years of experience in this sector, Carroll also adds that the Liebherr remote diagnostics system is very important. Despite the remote sites, a Liebherr service employee can connect to the crane control system of the crane from his office. If a problem arises, the Liebherr expert can provide immediate support without having to undertake a long journey.

Robust and safe – LRT rough terrain cranes

The two Liebherr rough terrain cranes – an LRT 1100-2.1 and an LRT 1130-2.1 – are ideal for use in rough, uneven terrain, such as the conditions in mining projects. With their robust design, the cranes can withstand a wide range of weather conditions.

Carroll says: “LRT rough-terrain cranes are known for their advanced safety systems, which helps us to achieve our goal of maximising safety on all projects. At the same time, their simple operation ensures additional safety and increases efficiency.”

The telescopic boom on the LRT 1100-2.1 has an impressive length of 50m. In addition to a maximum lifting capacity of 130 tons, the LRT 1130-2.1 features a powerful telescopic boom with a total length of 60m.

Carroll says, “The cranes are easy to transport and set up, which saves a considerable amount of time and resources on sites. This will improve our overall project and cost efficiency.”

“We are delighted that we will be able to handle a wider range of projects with the new cranes.”