Steinmüller Africa’s intelligent engineering services has expanded with the addition of the Elios 3 caged inspection drone to its fleet, enhancing inspection capabilities and reducing costs for power stations by reducing the need for human inspection services.

“The drone is designed for inspections in dangerous, cluttered, and confined spaces. It’s a safer, more accurate way to gather information in hazardous areas,” says Carel van Aswegen, Group QC/NDT Manager, Steinmüller Africa.

“Using this drone allows us to cut downtime for inspections — sometimes by as much as 50% — not only through the accurate data it provides but also thanks to its accessibility,” says van Aswegen, “we can inspect damage in boilers once they cool down to around 50°C, without waiting for permits required for human entry or installing scaffolding and sky climbers. The drone also identifies damage locations with greater accuracy.”

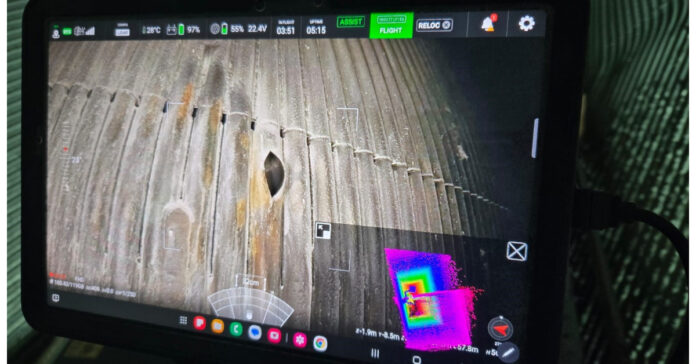

Developed to be more than just a robust drone, the Elios 3 is the first indoor mapping and inspection drone capable of transforming asset data into digital insights. Its carbon fibre protective cage (measuring 18.9″ in width and 13.8″ in height) provides 360-degree collision tolerance, allowing it to navigate tight, complex environments without risk of damage. The drone’s advanced stabilisation system ensures smooth, stable flight even in turbulent conditions, this is crucial for capturing high-quality visual and thermal data.

Equipped with a 4K camera, flight control sensors, inertial measurement unit (IMU), magnetometer, barometer, thermal imaging sensor, 3 computer vision cameras, time-of-flight (ToF) distance sensor, and LiDAR technology, the Elios 3 delivers high-resolution imagery and enables precise 3D mapping, even underground. This allows for the creation of accurate digital twins of inspected assets, with intuitive reporting on a 3D model and real-time situational awareness built into the piloting app.

The Elios 3 also features advanced flight path detection, allowing it to autonomously navigate complex, GPS-denied environments with precision. Real-time data transmission enables inspectors to monitor live feeds and make quick, informed decisions, while its modular payload capabilities offer additional flexibility.

Steinmüller Africa has even used the drone for post-incident investigations. “A client recently experienced an explosion on-site. We quickly mobilised the drone to assess the damage for safe entry, providing the team with exact locations and live footage of the surroundings, enabling faster, more targeted care,” van Aswegen explains.

Beyond current client benefits, the Elios 3 opens new opportunities for Steinmüller Africa. “The drone can be used almost anywhere it’s unsafe, impractical, or financially unviable for a person to go,” he adds. This includes coal storage tank facilities, grain silos, underground mines, manufacturing plants, warehouses, boilers, tunnels, cell phone towers, railway transport tankers, and bridges.

Steinmüller Africa began using Elios drones in 2017, becoming the first company in South Africa to acquire the technology from Swiss manufacturer Flyability.