THE mobility revolution stands out as a key force behind climate protection efforts, with synthetic fuels derived from renewable energy sources emerging as a promising solution to reduce CO2 emissions.

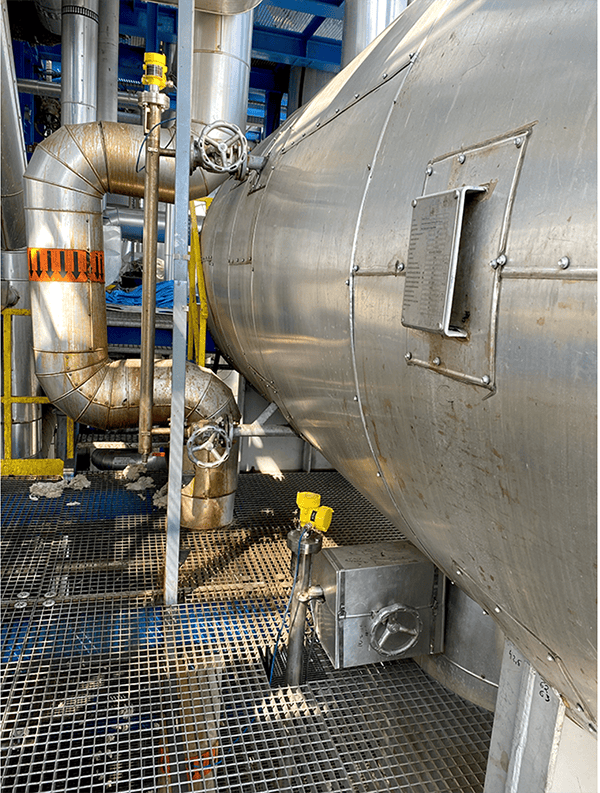

A prominent player in this field is the Polish company Ekobenz, which specialises in producing bio-hydrocarbons. The company utilises advanced manufacturing techniques where VEGA sensors monitor levels and interfaces, essentially overseeing separation layers.

Synthetic fuels are created through chemical synthesis and represent a viable alternative to fossil fuels, particularly those derived from petroleum. One of their significant advantages is that it can be used in existing vehicles, allowing the replacement of conventional fuels and considerably cutting down on CO2 emissions.

To produce synthetic fuels, Ekobenz harnesses ethyl alcohol obtained from waste products with a catalyst triggering the bio-hydrocarbon synthesis. This process generates bio-butane-propane (bio-LPG), liquid bio-hydrocarbons (bio-petrol), and aromatic bio-hydrocarbons.

“To help reduce CO2 emissions, we’ve developed unique technologies worldwide,” explains Piotr Kobiec, head of production at Ekobenz. The company boasts a cutting-edge processing plant outfitted with innovative automation solutions and top-notch instrumentation technologies. A vital component of this plant is the VEGA sensors, which facilitate reliable monitoring of critical process parameters.

In a 3-phase separator, the VEGAFLEX 81 sensors, based on the guided wave radar principle, measure the hydrocarbon/water interface. The data they provide is essential for managing the amount of water pumped from the container to the wastewater treatment plant, thus preventing any unintended escape of hydrocarbons. Continuous level measurement within the columns’ floors is also a necessity.

Stable monitoring of the medium’s level in the production process is crucial. This is achieved with multiple VEGAFLEX 86 radar sensors installed in a bypass tube, delivering precise measurements even under extreme pressure and temperature conditions.

VEGA’s measuring instruments are recognised across industries for their accuracy and maintenance-free operation. Before deploying VEGA sensors, Ekobenz utilised level transmitters with magnetic floats that underperformed due to complex operations, measurement inconsistencies, and frequent cleaning requirements. VEGAFLEX sensors offer reliable measurements for nearly any liquid, even in challenging conditions such as buildup, steam and foam.

These sensors can endure constant high temperatures, ranging from 140 to 280 °C, and meet the company’s Ex certification requirements following ATEX standards.

For more information: https://www.vega.com/en-za