Brady RFID Solutions: Engineering durability and compliance for rail industry challenges

AS rail operators face mounting pressure to improve asset management, reduce maintenance costs, and meet stringent safety regulations, RFID technology has emerged as a critical enabler of digital transformation. Cape Business News spoke to Brady RFID Solutions about its latest rail industry solutions and how it maintains high safety standards.

Brady answers some pertinent questions:

Q. Can you describe specific material and adhesive technologies used in your labels / RFID tags that ensure durability over the expected lifecycle of rail components? Also, what accelerated testing or field data do you have to back up claims of longevity in those harsh conditions?”

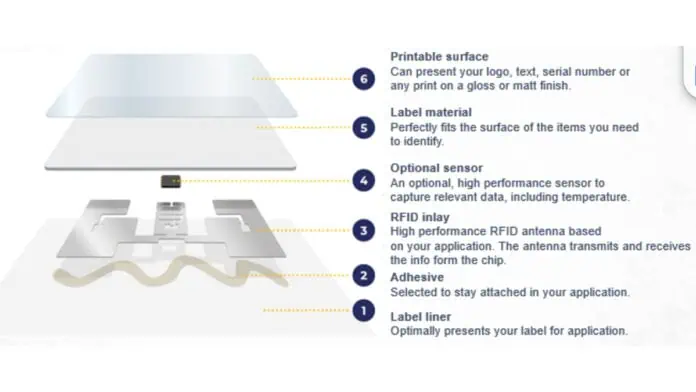

A. Brady can customise the RFID label construction (face materials, adhesives and RFID inlays) according to the customer’s needs and specifications.

We have an extensive range of highly resistant materials (PET, PP, PA, PI, Vinyl etc.) that can be chosen as the required face materials for the RFID label. Also, we have different strong adhesives (permanent acrylic, rubber-based etc.) that can be applied according to the application surface. With the good knowledge of materials and combining the RFID inlays, we can create the high-performance RFID label construction for different harsh conditions, such as resistance to chemicals, UV, water, extreme heat and cold etc.

Our lab can also perform the necessary accelerated testing, such as the weatherability test, UV light resistance test, humidity and temperature resistance test, chemicals testing, physical testing (peel adhesion test, abrasion test etc).

Q. How do Brady’s RFID solutions (tags, fixed & handheld readers) integrate with existing rail asset management systems or IoT platforms? What standards/communication protocols are supported? Is there support for remote/wireless data capture (eg. from tags on moving rolling stock), and how is tag readability ensured in complex environments with metal, interference, etc.?

A. We support MQTT(s), HTTP(s) protocols as a standard. On the wireless side, we can support WLAN and LTE in selected areas. Readability is ensured with a correct label and correct antenna placement.

Q. Maintenance and safety inspections are critical. How do your printing/identification/software tools support the traceability of components (for example, identifying and tracking cable harnesses, brackets, fasteners) across multiple inspection cycles? Is there functionality for verification (eg, reading/auditing RFID or barcode data), condition-based maintenance, or integrating identification with maintenance schedules?

A. Every RFID tag has its own unique identity. This enables tracking the usage of the assets. RFID tag is also passive, so if it is not mechanically broken, then its lifetime is not limited. Every reading can be tracked, and additional information and be added.

Q. The rail sector is heavily regulated. Which international or regional standards do Brady’s products comply with for use in rail applications (e.g., EN, DIN, ISO, railway safety norms)? How do you ensure that labelling (e.g. safety signs, ratings, nameplates) meets requirements for visibility, retro reflectivity, flame resistance, etc.? Also, what is your approach to quality assurance and certifications for these products?

A. Brady manufactures quality identification solutions worldwide and takes into account all relevant regulations and standards, including the European Union’s CE-label.

More specifically, our Lab is testing and securing compliance of selected materials with the following standards:

- NF F00-608:1995

- EN 50343:2014 + A1:2017

- EN 5545-2:2020 + A1:2023

- DIN VDE 0472-815:1989-03

- BS 7870-3.22:2011